Within the midst of the COVID-19 pandemic, when his friends engaged themselves in making social media content material, Mohammed Azhar Mohiuddin noticed this as a possibility to delve into entrepreneurship and deal with urgent points akin to plastic air pollution.

From a younger age, he dabbled in varied ventures from web site improvement, emblem designing, to working a cloud kitchen to promoting burgers from residence. His entrepreneurial spirit was fueled by a need to resolve issues quite than solely chasing monetary positive aspects.

“In 2019, I puzzled what I used to be actually even chasing. Cash? That may come even after I began specializing in fixing actual life issues,” he says.

Whereas researching on high world environmental points, Azhar discovered that there have been a number of consciousness campaigns and protests worldwide on plastic air pollution. “Except we have now an alternate, there isn’t a solution to curb plastic utilization. Whereas large manufacturers can afford jute and fabric luggage however medium and small companies which comprise a bulk of the Indian market proceed to make use of plastic luggage,” he provides.

“One of many main causes behind the in depth use of plastic luggage are its properties. It’s water-proof, thermal, sturdy, lightweight, and has good tensile energy. I needed to seek out an answer that might mirror the properties of plastic whereas being eco-friendly and cheaper than paper, fabric, and jute alternate options,” he says.

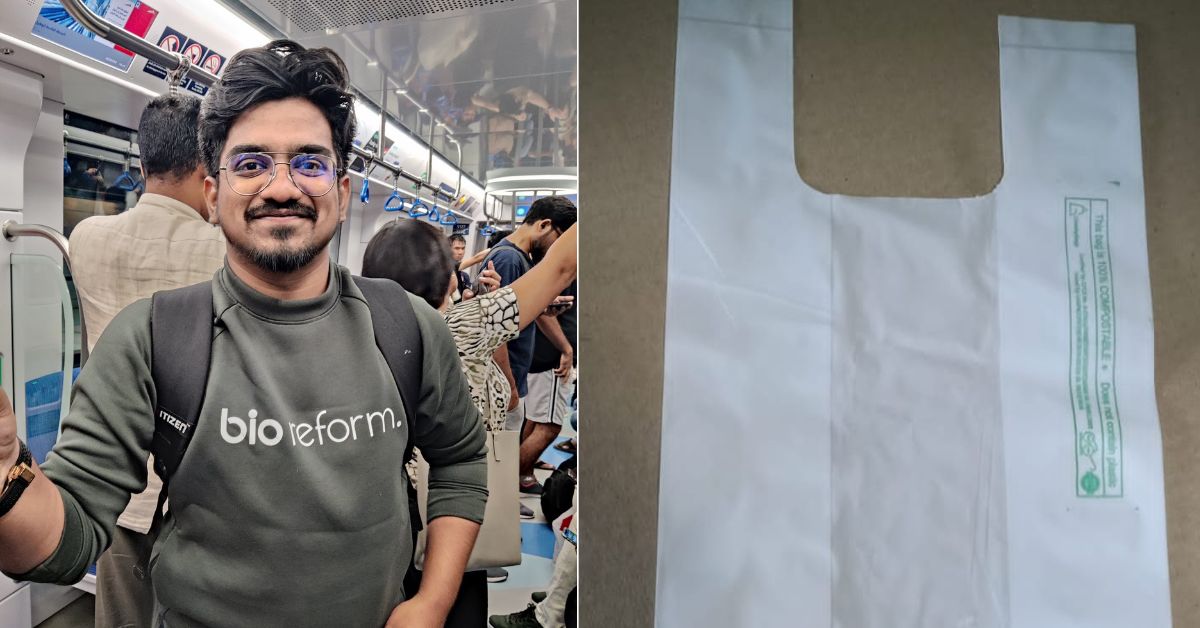

This quest led him to launch ‘Bio Reform’, a Hyderabad-based startup that manufactures compostable luggage utilizing corn waste, sugars, cellulose, and different pure parts into sustainable biopolymers. Previously two years, it has changed over six million plastic luggage.

Challenges on the way in which

Azhar drew his inspiration from a biopolymer analysis paper relationship again to the 1800s.

He began finding out a couple of biodegradable polymer, PBAT (Polybutylene adipate-co-terephthalate), that’s derived from plant-based sources akin to corn and potatoes. This fashioned the idea of a brand new enterprise endeavour for Azhar.

The following step was to seek out the precise equipment to course of the uncooked supplies into finish merchandise. His willpower was examined when he confronted a number of setbacks akin to encountering fraudulent schemes and operational difficulties within the early levels.

“My uncle and I went to Delhi to test the equipment after we got here to know a seemingly promising alternative but it surely turned out to be a rip-off. The contact individual was not answering our calls and his promised location turned out to be a barren land. It was very traumatising for us. I had someway satisfied my mother and father and now I didn’t need to return residence empty-handed,” he says.

Decided to not let this setback deter them, Azhar and his uncle took a leap of religion and reached out to a different contact in Gujarat, which got here with its personal collection of challenges.

Touchdown throughout a curfew amidst the COVID-19 pandemic, Azhar needed to spend many of the evening stranded on the highway because the resort denied check-in as a consequence of a sudden RT-PCR report requirement. “However the perseverance paid off once we witnessed the equipment and its dwell demonstration the subsequent morning,” he provides.

Across the identical time, he obtained Rs 1 crore funding from the Journey Park incubator programme. In early 2022, he inaugurated his manufacturing facility in Hyderabad on the age of twenty-two.

Changed 6 million plastic luggage

Organising a producing unit from scratch was itself difficult for Azhar. He needed to handle the intricacies of a producing enterprise and the pressures of balancing tutorial commitments.

“On the inauguration day, my uncle, who was additionally the co-founder, give up the corporate citing some private causes. I attempted to stability each my research and the operations of the corporate – from gathering uncooked materials, helping employees to fabricate luggage, delivering the merchandise out there. I used to sleep in a nook within the manufacturing facility,” shares Azhar, who was then within the third 12 months of his faculty.

This continued for a 12 months however Azhar needed to shut the manufacturing facility down after he was unable to make earnings to maintain the corporate. “I got here again to zero. In the meantime, I had 14-15 backlogs in my engineering. In a bid to stability each jobs, I failed at each. It was a worrying scenario for me,” he provides.

But, via sheer grit and relentless effort, the civil engineer not solely cleared all exams but in addition secured a funding from an investor, and ultimately revived his enterprise in a few months.

Right this moment, his firm is manufacturing 4-5 lakh carry luggage, biomedical waste luggage, rubbish luggage, meals pouches, and e-book wraps. Apparently, Azhar says, these luggage are compostable and could be decomposed inside 180 days. Within the final two years, his startup has changed greater than six million plastic luggage by commercialising within the B2B chain.

Final 12 months, he clocked an annual income of Rs 1.8 crore.

Mohd Sami Uddin, co-founder of Nation Rooster Co, has been utilizing Bio Reform luggage for greater than a 12 months. Sharing his suggestions, he tells The Higher India, “We needed to concentrate on sustainable packaging as a lot as doable. Previous to Bio Reform luggage, we have been utilizing plastic luggage. In a while, we additionally tried different sustainable luggage however sadly, they have been neither meals grade high quality nor superior.”

“At occasions, the shoppers would complain to us if some sharp bones would come out from low-grade luggage. Nevertheless, Bio Reform luggage meet all our necessities and could be simply sealed as nicely, just like plastic. Apart from, there was not a lot distinction from the value level additionally. The plastic luggage would value us Rs 160 per kg whereas Bio Reform luggage value Rs 180 per kg,” he provides.

On the particular person degree, Azhar says that he has spearheaded a motion in direction of India’s imaginative and prescient to grow to be single-use plastic-free.

“Points associated to plastic air pollution usually are not restricted to affecting aquatic life and animals anymore. Right this moment, microplastic has reached our bloodstream. Bottled water accommodates microplastics. Addressing this is a crucial and pressing drawback,” he says.

“I’m glad I’m able to contribute my half. It’s generally taxing to not lead an everyday faculty life however ultimately, it’s all price it. I really feel content material after I return to sleep. However rather more must be carried out to make India plastic-free, and I’ll proceed to attempt for it,” he provides.

Edited by Padmashree Pande; All photographs: Mohammed Azhar.